|

|

|

|

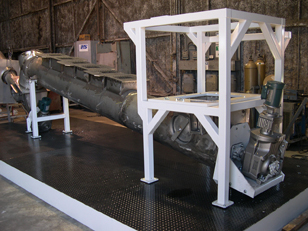

Manufacturing

Micro-Waste Corporation® has fulfilled the requirements of the Texas Board of Professional Engineers to offer and perform engineering services. Micro-Waste Corporation® also has engineering and manufacturing capabilities located near our corporate office in the Dallas-Fort Worth metroplex in Texas. When appropriate, standard industrial products are used to allow the customer to obtain replacement parts locally. The custom manufacturing and fabrication is performed by a worldwide recognized leader in high performance material handling equipment. The capabilities include a full machine shop and metal fabrication facility with state-of-the-art laser cutting and water jet cutting. The Micro-Waste® Disinfection System™ and components design are performed using AutoCAD, and the manufacture and fabrication are fully integrated onsite to ensure highest quality and rapid turnaround. For the highest wear items on the system, the shredder cutters and spacers, Micro-Waste establishes specifications with and obtains the components from its local manufacturer recognized internationally which specializes in shredder design and manufacture.

|

©Copyright 2007-2022 Micro-Waste Corporation®. All Rights Reserved.

Micro-Waste®, Micro-Waste® Disinfection System® and MDS® are trademarks of Micro-Waste Corporation®.